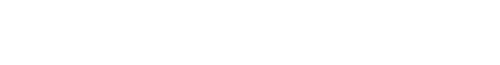

Leading Global Solder & Flux Manufacturer

Amerway is a leading global solder and flux manufacturer dedicated to providing the highest quality products to service the stained glass, industrial and electronic industries. Our product line includes:

Our Process

The following is a summary of the step by step procedures used by Amerway to alloy, analyze and statistically monitor each production lot of Amerway solder.

STEP 1. ALLOY

Upon receipt of incoming metal a receiver number is assigned to the material. Every shipment of tin and lead received is analyzed to verify agreement with the supplier’s certificate of analysis. Drillings are taken from 10 different randomly selected ingots. These drillings are then remelted and tested on our state of the art spectrograph.

When alloying the metal into solder, a lot history is initiated and utilized in identifying the components and weights used to form the lot, (sometimes referred to as the charge). The history of every lot can thereby be traced to the origination of all the materials from which it was created.

STEP 2: ANALYZE

After the metal has been melted and mixed, an initial pot sample of the lot is then taken for analysis. The sample is prepared on a lathe, then analyzed three times on the spectrograph. This insures there is no separation within the sample. The results are then averaged automatically by the PC which is an integral part of the Spectrolab. The results are then compared to the customer’s specifications and the software program is set up to automatically identify any elements that are not within the specifications.

This same process is performed two more times as the pot is being cast into product. In doing this, we are able to monitor any changes within the lot during the casting process. This is all part of our in process statistical control.

STEP 3: STATISTICALLY MONITOR

After all of the metal has been cast into product, the results of all of the analytical tests (9 of them) are stored in the Spectrolab statistical data control program.

As you can see, the quality and consistency of Amerway’s solder is very closely monitored. The bottom line is that the customer can be sure every lot of material is exactly what the certificate of analysis (which accompanies each shipment) indicates.

A Different Service Approach

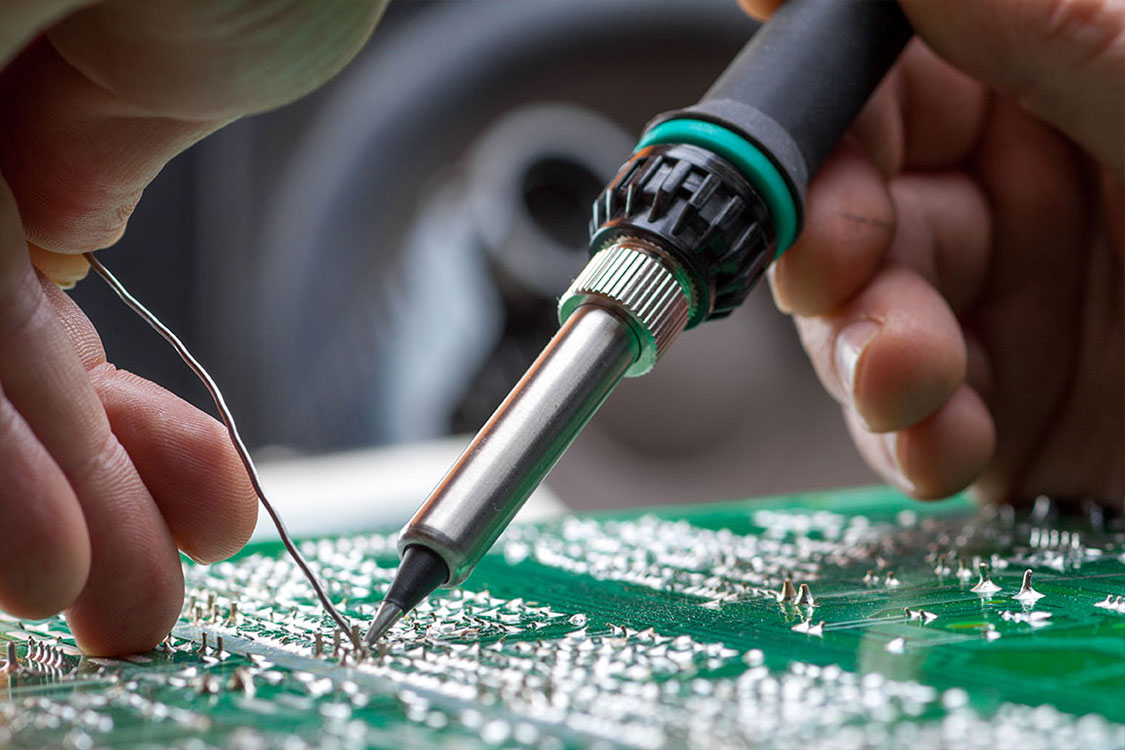

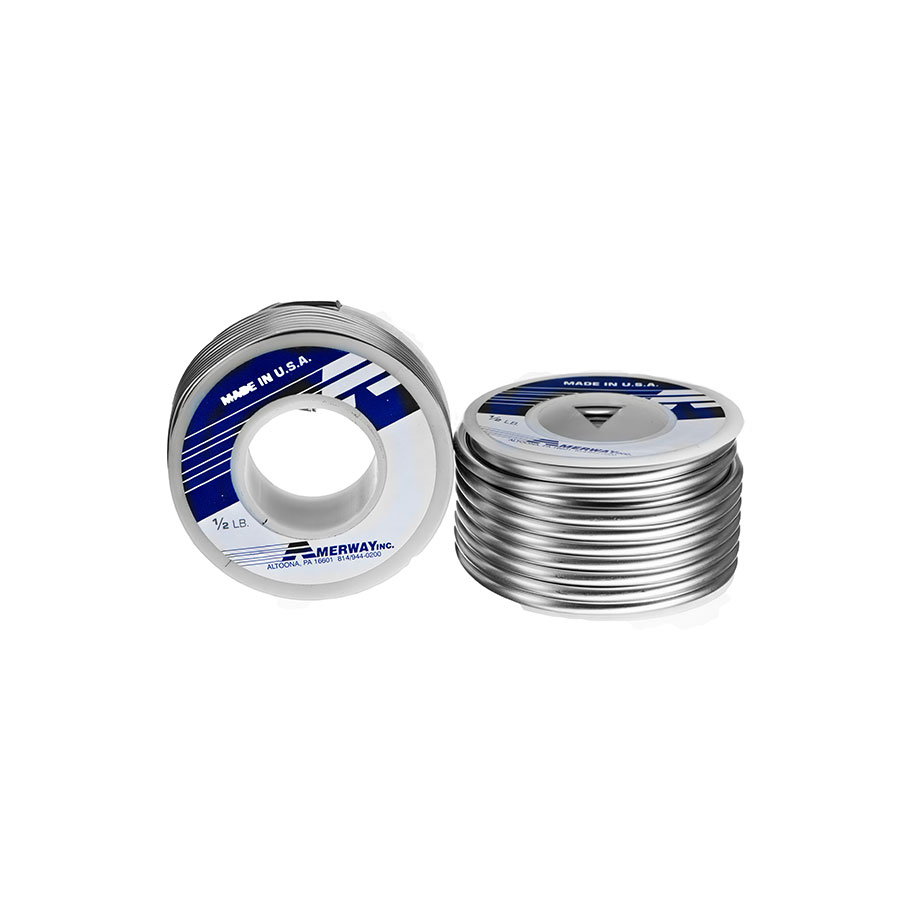

Amerway Inc. is a family owned American company with more than 50 years of experience. We maintain a staff of highly motivated professionals dedicated to providing superior quality products. Thanks to our size and philosophy, we maintain a leaner operation with shorter production times and lower overhead. This allows us to deliver quality products with faster turnaround at the most competitive pricing.

Faster Product Turnaround

Many products have 24 hour shipping allowing you to take advantage of just in time inventory, lowering your cost and improving your cash flow. Emergency windows are scheduled in our production timetable to react to those customers who may have rush orders.

As a factory direct supplier, we can also tailor the product to your individual needs, making us the superior choice for all of your solder and flux needs.

In-House Expert Staff

Amerway maintains an on-staff metallurgist and a certified chemist to ensure cutting-edge technical assistance. Our team of highly-trained and knowledgeable engineers is equipped and empowered to deliver creative, expert solder and flux solutions. This investment in expertise allows us to outperform our competition and supply the highest quality service and solder and flux products in the industry!

Our Guarantee

Through proprietary refining techniques, Amerway Inc. produces the finest solder in the world. We supply precisely what you need when you need it. With our personal service, you are sure to receive a product whose production process is continually monitored, tested and analyzed to provide you with the consistency, efficiency, repeatability and quality without peer. Only the highest quality Grade A Virgin Metals are engineered to your exact specifications and done so by professionals combining more than fifty years experience in the industry.

Certificate of Analysis: Our solder pot analysis program monitors 17 elements and a Certificate of Analysis is provided with each shipment.

Made in the USA

Quality service. Quality products.

American Ownership

Family owned and operated.

Highest Quality

Providing the best quality to be found anywhere in the electronics industry GUARANTEED!

Our Clients

I am writing you to tell you how much my students and I like Amerway’s lead-free solder. As a public school we avoid lead products in all of our art classes, where applicable, Amerway has provided us with quality solder that allows my students to easily create stained glass art work. I would recommend Amerway lead-free solder to anyone who wishes to avoid lead and looking for a smooth bead.John Anthony Muth, Skyline High School

Amerway has been our best selling solder for the past 8 years. Mixing together a great price and quality alloys made from 100% virgin metals create a winning combination- and, it’s Made in the USA.Sunshine Glassworks